Many of CMR’s team members participated this week in Carnegie Mellon’s Build 18 event – with students working all week on an ECE/CS related project. Not to miss a great opportunity to work on race cars, CMR was well represented.

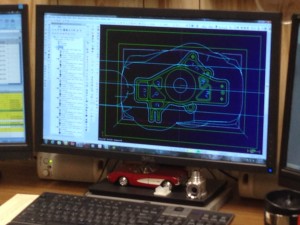

One project wired rotary potentiometers, pressure sensors, tapped the throttle position sensor on CMR 67, and connected them to a computer to play Need For Speed using the car’s controls. Crowds were gathering around to see.

A custom lap timer was also made for keeping track of our testing times, in addition to a reprogrammed RC car using a custom software package that will translate onto next year’s GLV controls system to increase sampling speed.

It was also an exciting process getting the car into the Gym, the looks we received from CMU employees was priceless.