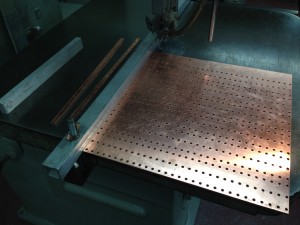

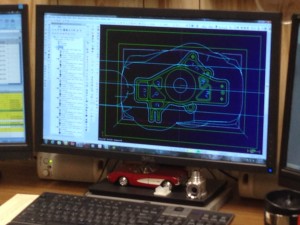

Where is the chassis?! Thanks to a heroic effort from our welders this past week, CMR 14e’s chassis has been sent to powder coating over a month earlier than in previous years. Our Garage looks empty now that tab production has ended. Notice to multitude of new tabs and chassis structure required by our 100% electric powertrain. Look forward to the shiny new chassis arriving next week!

Not to stay idle, CMR took this opportunity of a clean Garage to show some local high school students who are interested in STEM careers around the Garage. It was great seeing young students excited about race car engineering!